|

|

Products >

Thermo Formed (PVC) |

|

|

|

|

| |

|

|

|

|

|

|

|

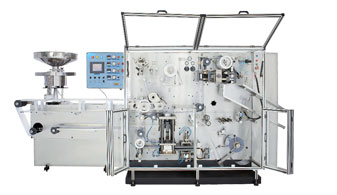

SALIENT

FEATURES : |

|

-

Intermittent

compressed air flat forming.

-

Continous rotary

sealing for high speed feeding and tight seal.

-

Separate embossing

station, performation station punching station.

-

Pick and place

mechanism for punched out blister packs which helps

in down line automation.

-

Edge to edge blister

cutting avoiding trim wastage.

-

Misfill detection of

tablet/capsules.

-

Batch coding/Printing

device.

-

Full functional P.L.C

unit with M.M.I haveing recipe settings.

-

Print registration

control device for calendar packs.

-

Dedicated feeders such

universal brush feeder for coated products, inclined

feeders for uncoated products.

-

Multifeeder mounting facility for kit packs.

-

Short change over time.

BASE MATERIAL

-

PVC opaque or transparent

-

PVC with PVDC

-

P.P., P.E.

|

|

|

|

LIDDING MATERIAL |

|

Heat sealable aluminium or glassine

paper

|

| |

|

FORMAT RANGE |

- Base

material

-

Width-230mm Maximum

-

Thickness-0.2-0.3mm

- Reel Dia-440mm

Maximum

|

|

|

|

LIDDING MATERIAL

FORMAT |

-

Width-226mm Maximum

-

Thickness-0.02-0.03mm

- Reel Dia-220mm

Maximum

|

|

|

Maximum forming Area : 220MM X

200MM

Maximum index length: 200MM

Forming Depth: 12MM

Output-400 Blister Packs/Min(For a typical pack size). |

|

|